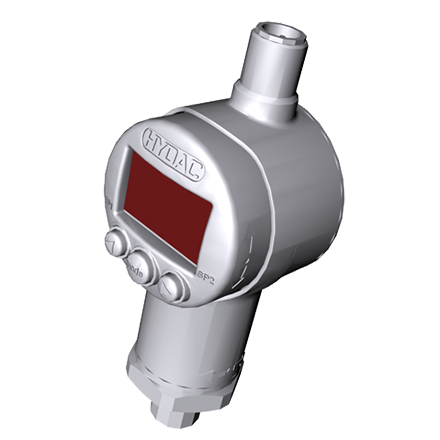

Sensors

The range of sensors includes products for the measurement of pressure, temperature, linear position, position, level, flow rate and rotational speed, as well as contamination and oil condition. In addition to products for standard applications, the product range covers special fields of application such as explosive atmospheres and applications with increased functional safety.

Product Search

Filter selection

Reset filter

Downloads for this category

CAD data can’t be found at the product category level. Instead, it can be found directly at an individual product level.

Media

Electronics. Product Catalogue.

Product brochure

EN

(12.49 MB)

Control Technology for Mobile Machines. Product Catalogue.

Product brochure

EN

(17.34 MB)

A Breath of Fresh Air in Electro-Hydraulic Cooling Control

Product brochure

EN

(6.24 MB)

Fluid Control Contamination Handbook

Product brochure

EN

(5.58 MB)

Particle Measurement Technology in Practice

Product brochure

EN

(1.85 MB)

Smart IO-Link products and solutions

Product brochure

EN

(6.62 MB)

Pressure transmitters for hydrogen applications

Product brochure

EN

(22.21 MB)