Your point of contact for a wide range of compressor types

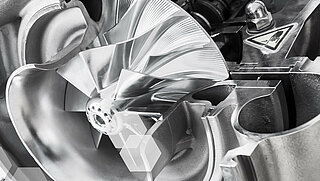

Turbo compressors

Turbo compressors, like axial compressors, are dynamic compressors. They are most often used in continuous process technology procedures. Because of the high loads your machines are exposed to, we offer efficient auxiliary systems for circulation lubrication or gas seals. HYDAC is your contact for the solutions of tomorrow.

Piston and diaphragm compressors

Piston and diaphragm compressors belong to the family of displacement compressors. They are used to compress gases in discontinuous processes when high compression ratios or pressures need to be achieved. They are set to become more important in future, for the compression of hydrogen. HYDAC can support you with its many years of expertise in lubrication and temperature control. We can also lower your costs over the long term with standardised system solutions.

Sustainability & standardisation

Renewable energy is gaining ground, and thus so are the associated technologies. HYDAC is already able to supply innovative lubrication systems for the sustainable operation of your system. Reduce your operating fluids considerably with our standardised and space-optimised applications.

Sustainability and standardisation in system technology: our product solutions

HYDAC gas panels

Seal gas seals are extremely sensitive to contamination. If the seals of your turbo machine are to last as long as possible, reliable filtration is needed for your seal gases. You can rely on the seal gas filters and panels in reliable HYDAC quality – compatible with single, tandem and tandem-labyrinth seals.

HYDAC bearing lubrication systems

Modular and standardised – HYDAC supplies an extensive range of highly efficient lubrication systems. Our degassing strategy rapidly lowers the amount of air in the oil, so the dwell time that is standard for the application is drastically reduced. Protect your wallet and the environment with our tried-and-tested Air-X technology.

HYDAC compact lubricating unit

Lubricating units enable efficient operation of process compressors by distributing, cooling and filtering lubricating oil. HYDAC has the perfect solution for small systems: our modular system HYLU is suitable for flow rates of <30 l/min. Optimise costs and make designing easier today.

HYDAC pump-transfer cooler filtration unit

Machines with crankshaft housing need special lubricating systems without their own tank. HYDAC can supply the optimum solution for piston compressors, diaphragm compressors and dosing pumps. Standardised and yet modifiable – our pump-transfer cooler filtration units are even suitable for explosion-protected spaces.

Functional safety

The industry poses very strict requirements on your process technology systems – all with the aim of maximising availability. As a contact, HYDAC can support you both in the successful implementation of reliable process workflows and in particular in compliance with the required safety regulations. We will work with you to optimise and modernise your systems with SIL-enabled components and smart sensors.

Functional safety in system technology: our product solutions

HYDAC electrohydraulic safety control system

Our tried-and-tested safety control system EHC-S meets the strictest requirements for the safe operation of your compressors in accordance with both IEC 61508 and IEC 61511. Benefit from the compact and modular design of our reliable poppet valve technology.

HYDAC electrohydraulic drive system

Process technology systems pose an increased hazard potential.

To accommodate this, HYDAC has developed the EHC-A: high reliability and accuracy despite small dimensions. Use our drives to control valves – even autonomously!

HYDAC electronic sensors

In systems that need to work with functional safety, special measurement equipment is needed. HYDAC can supply application-compatible sensors for fluids and gases including hydrogen. Find out about our broad product portfolio of sensors with SIL certification.

Balance of plant

Always focused on the optimisation of your system availability – HYDAC is your contact for process monitoring of your compressors. Thanks to our worldwide range of services, we can support you in the maintenance and modernisation of your system. You too can extend the service lives of your fluids thanks to our tried-and-tested fluid conditioning systems in conjunction with our coordinated online monitoring.

Balance of plant in system technology: our product solutions

HYDAC Varnish Elimination Units

Our user-friendly VEU modules effectively remove oil degradation products from mineral oils and thus provide a longer fluid service life for your lubricating and hydraulic oils. This process not only guarantees greater system safety but also reduces your costs. Find out more about our modular power units.

HYDAC dewatering unit FAM

Is condensing process steam contaminating your oil-hydraulic systems? Ensure sustainable quality in your hydraulic fluids with the HYDAC FluidAqua Mobil – our modular dewatering system series with permanent moisture monitoring increases both service lives and your system availability.

HYDAC ContaminationSensor Module Economy

To ensure that your ball-bearings are always optimally supplied with lubricant in perfect condition, we supply fluid condition monitoring modules – and have been doing so for over 20 years. Find out about the many advantages of using our tried-and-tested CSM-E product series for the maintenance of your system.