Your innovative partner in test bench construction

System components for fuel cells

In the future, hydrogen will become an increasingly important medium in many areas – including test bench technology. To be prepared for tomorrow's challenges, rely on HYDAC as your partner for test benches designed for fuel cell components and hydrogen components. As a driver of innovation for many years, we impress with our media conditioning, flushing, process monitoring and much more.

System components for electrolysers

In an electrolyser, electrical energy is used to split water into its components – oxygen and hydrogen. HYDAC provides solutions for your electrolyser testing. We find the best custom solution for you when it comes to cooling and controlling the temperature of various media.

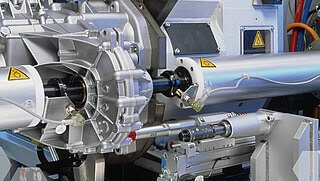

Electrical drives and gears

Electromobility is making a vital contribution to decarbonisation. Test bench technology ensures the functionality of these vehicles. That's why we focus on supporting your end-of-line test bench construction. Thanks to many years of expertise and a worldwide presence, HYDAC is your contact for the imminent questions surrounding test bench technology in the context of electromobility.

Condition monitoring

To be able to monitor the quality of the media that are conveyed to your system and test specimens with precision, comprehensive condition monitoring is essential. We ensure this all-inclusive service for you with media monitoring and analysis according to ISO 4406. Rely on our years of expertise in test bench construction – a conversation with us is worth your while.

Condition monitoring in test bench technology: our product solutions

HYDAC flow rate sensor

Measure the required volume precisely with our electronic flow rate sensor in the EVS 3100 series - suitable for viscosities of 1-100 cSt. Optimise your condition monitoring with HYDAC's technology.

HYDAC Contamination Sensor CS 2000

Pressure ports up to 40 bar – not a problem for our stationary sensor CS 2000. Specially designed for applications in test benches and servo hydraulic systems, it measures the contamination in your fluids.

HYDAC Contamination Sensor Module 1000

Are air bubbles distorting your fluid analysis? The CSM 1000 from HYDAC is the online monitoring system for the measurement of solid particle contamination. Find out about our CSM 1000 series – the optimal complete solution with integrated air bubble suppression.

HYDAC Contamination Sensor Module 2000

Our CSM 2000 system for detecting solid particle contamination in your hydraulic fluids sustainably optimises your system availability. Equipped with an alarm function, it reliably identifies the cleanliness of your test bench fluid.

Predictive maintenance

High system availability doesn't just lead to high productivity, it saves time and costs. Operation without downtimes can only be achieved with permanent monitoring – digitalisation makes this possible. Smart sensors analyse the test bench 24/7, enabling forward planning in terms of maintenance and ordering spare parts. We help you to design your test bench to be as efficient as possible.

Predictive maintenance in test bench technology: our product solutions

HYDAC CMX suite

Our CMX platform helps you to digitalise your test benches. The innovative hardware and software kit is the basis for intelligent integration of your systems – whether this is locally on your server or in the cloud.

HYDAC Portable Data Recorder HMG 4000

A robust design and user-friendly operation – this is what sets our portable HMG 4000 measurement and data gathering device apart. It's especially well-suited to applications in service, maintenance and test bench technology.

HYDAC p0-Guard pressure switch EDS 3400

The EDS 3400 enables the accumulator pre-charge pressure (p0) to be monitored and the accumulator charging function to be controlled. This is how our pressure switch supports predictive maintenance of your system.

HYDAC Differential Pressure Transmitter HPT 500

Our cost-optimised HPT 500 series is ideally suited to continuous monitoring of the filter element contamination level in your pressure filters. Learn more about our different versions: IO-Link, CANopen and many others.

HYDACLab® Oil Condition Sensor

Precise, constant and online: the HYDACLab® 1400 is ideal for digital condition monitoring of standard oils. Continuous monitoring of your fluids is the result. HYDAC is on hand to help you at any time.

Flexibility & modularity

HYDAC is your flexible partner for test bench construction and development. With our application-specific simulation tools, we ensure that you use the optimal components for your application. To this end, we offer everything from individual components right up to turnkey subsystems. Our applications are always based on the current guidelines in terms of safety, the environment and energy. Let us work with you to design your test bench.

Flexibility in test bench technology: our product solutions

HYDAC MultiRheo Filter

The MultiRheo filters in the MRF series are filter housings for use in open systems which are continually exposed to external contamination. The candle filter elements protect components such as nozzles or working filters, for example in function test benches.

HYDAC oil filtration

As an expert in fluid power applications, we provide you with efficient oil conditioning to help you reach your fluid cleanliness requirements. Rely on HYDAC's modular filter designs.

HYDAC plate heat exchangers

Whether it's brazed or gasketed – HYDAC offers you a comprehensive range of plate heat exchangers. We find the right solution for your test bench, tailored to your challenges.

HYDAC fluid-water cooling system

Tank, circulation pump, plate heat exchanger and optional temperature control: our FWKS is a compact passive cooling system for your cooling circuits. Learn about the many advantages of our system solution.

HYDAC cooling unit

The HYDAC RFCS is an active cooler which independently regulates the coolant temperature down to the required set point that has been configured. Our Plug & Play solution gives you lots of options for custom test bench configurations.

HYDAC cooling systems

Custom cooling systems tailored to the requirements of your test bench – HYDAC makes it possible! Take advantage of our decades of know-how in temperature control.

HYDAC simulations

From development and analysis right up to commissioning: HYDAC supports you in the development of electro-hydraulically operated machines and application-specific simulation tools. In cooperation with our engineering service provider,marpitec GmbH.

Flexibility in test bench technology: our product solutions for hydrogen

HYDAC gas filtration

As an expert in a variety of applications, we offer efficient gas filtration with our HYDAC GF series, enabling you to achieve the required cleanliness level. Find out about our expertise in hydrogen applications.

HYDAC plate heat exchangers

The heat transfer between two media is always kept at a required temperature by plate heat exchangers. Stainless steel and brazed with nickel – we have the right solution for you

HYDAC pressure sensors

To monitor operating parameters we developed a range of pressure sensors for hydrogen applications from 0 to 1050 bar. Designed for the different pressure ranges required, e.g. 0 to 2.5 bar or 0 to 4 bar. Perfectly monitored processes thanks to HYDAC.

Our references

Process reliability and system availability for automotive suppliers

Technical cleanliness for longer fluid service life √ Save costs and resources √ Boost system availability √ Low particulate contamination → Find out more!

Read customer success story